Robotics PhD Project We have a Fall 2024 opportunity for a Ph.D. student at the University of Louisville in the area of fabric with embedded sensors and actuators for soft robotics. Students with Masters degrees in electrical engineering, mechanical engineering, textile engineering and natural sciences (physics/chemistry) are sought. This is an experimental project. It involves computer programming, modeling, …

Author Archives: cindy.harnett@louisville.edu

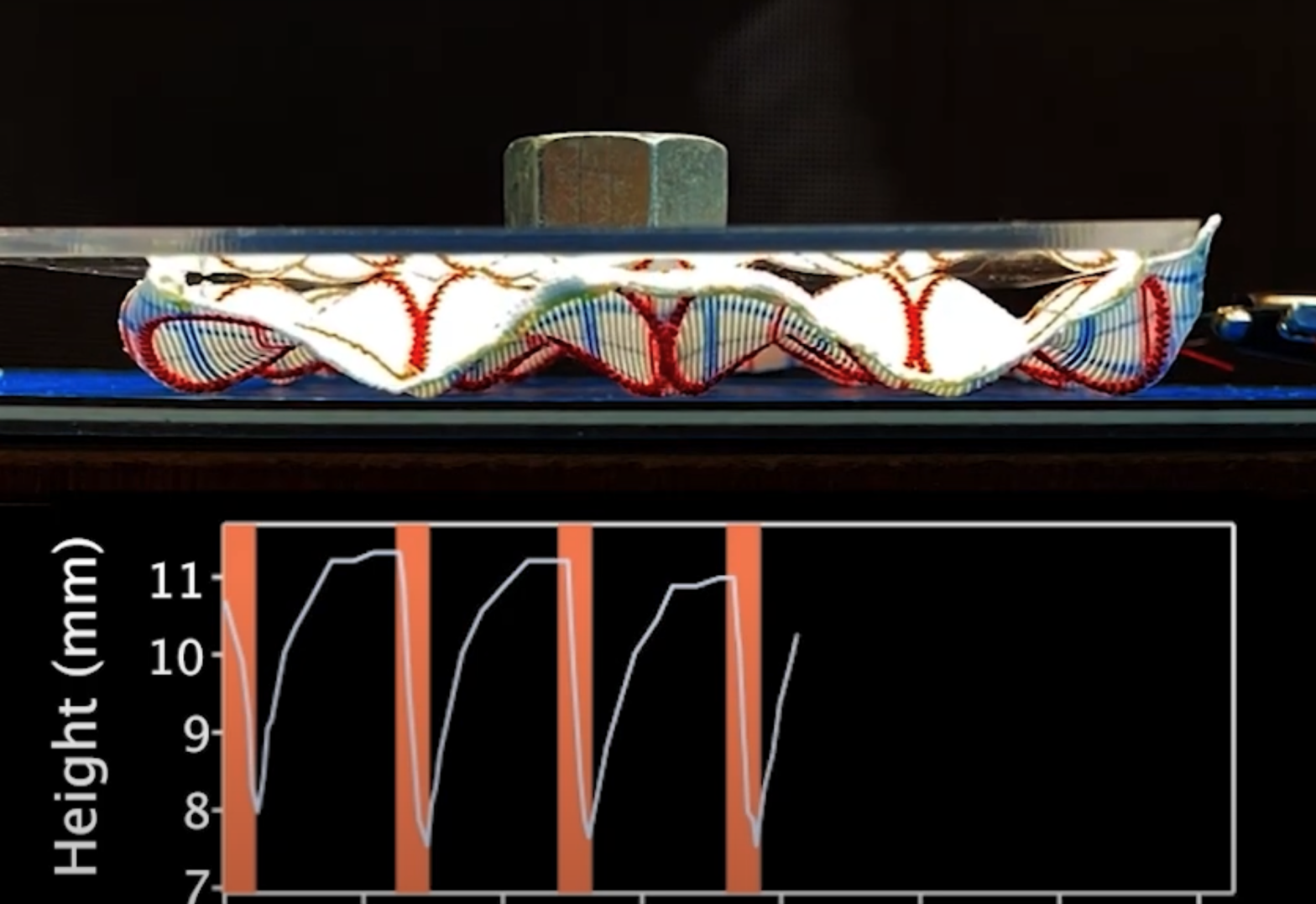

Morphing fabrics from elastic and wire

We have developed soft actuators called “Strained Elastic Membranes with Adjustable Modulus Edges” (SESAMEs). These fabric-based modules are made by stretching spandex fabric on a frame and installing shape memory wire borders using machine embroidery. When released from the frame, the SESAMEs take on a saddle shape that lets the wire bend a little and …

Bringing the current

Previous REU student Nathan Song made his way to Boston this summer to present his work at the IEEE International Conference on Flexible, Printable Sensors andSystems (FLEPS). Although the weather cancelled flights across the coast, Nathan made it. He presented a new way to connect up microdevices using flexible microgrippers to clip onto wires and …

Thermally-driven MEMS fiber grippers

In our latest paper, we investigate microelectromechanical structures (MEMS) as fiber grippers with a new focus on temperature-driven motion and resistive temperature sensing. Article here:

A porous circuit board

Our lab is thinking about how to connect flexible and stretchable electronic circuits together. Whether it’s a soft silicone stick-on “electronic tattoo” or a fabric based e-textile, no one wants to plug in a huge lumpy connector at the edge of the device. However, these circuits usually need connectors for power and communication. We are …