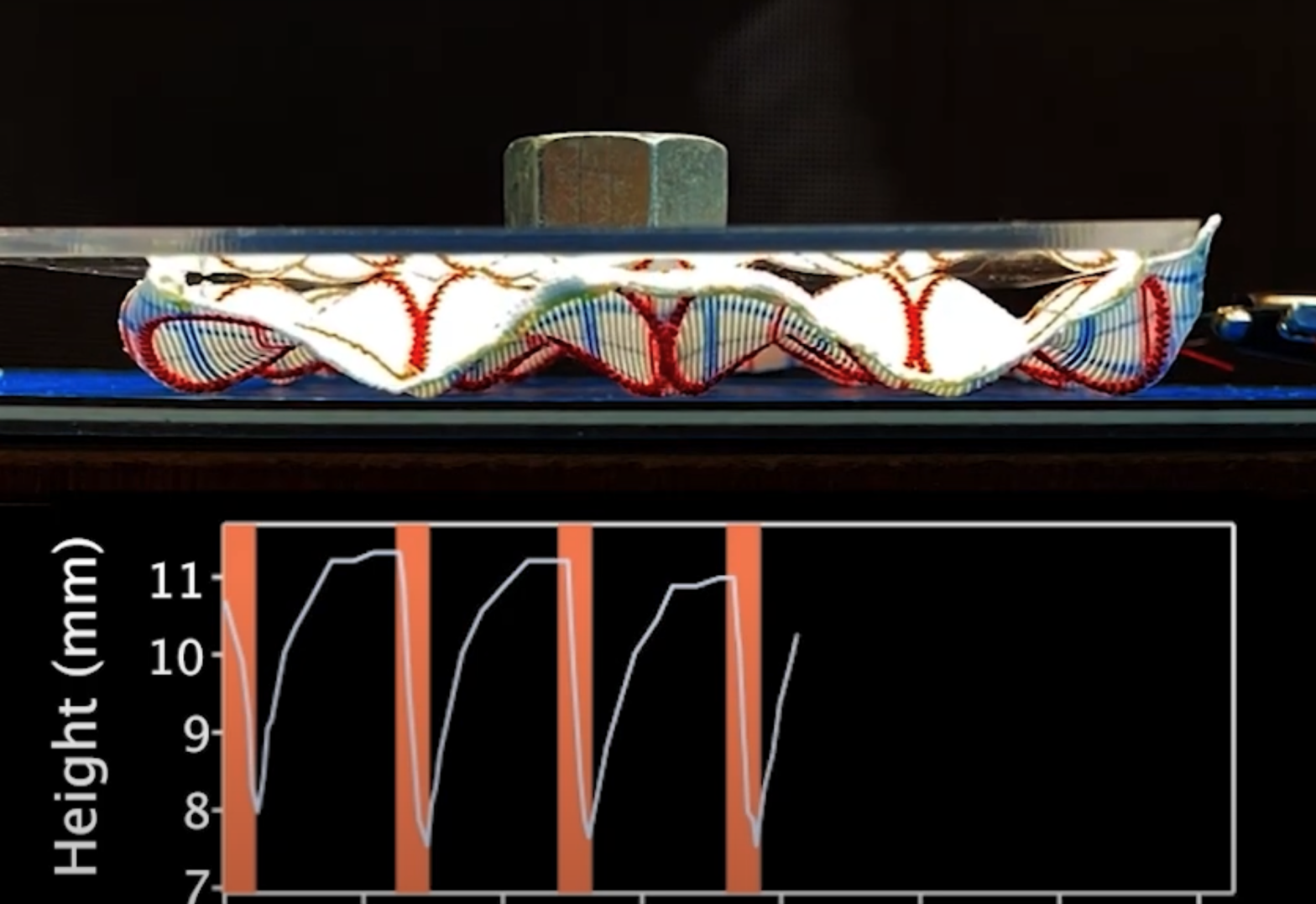

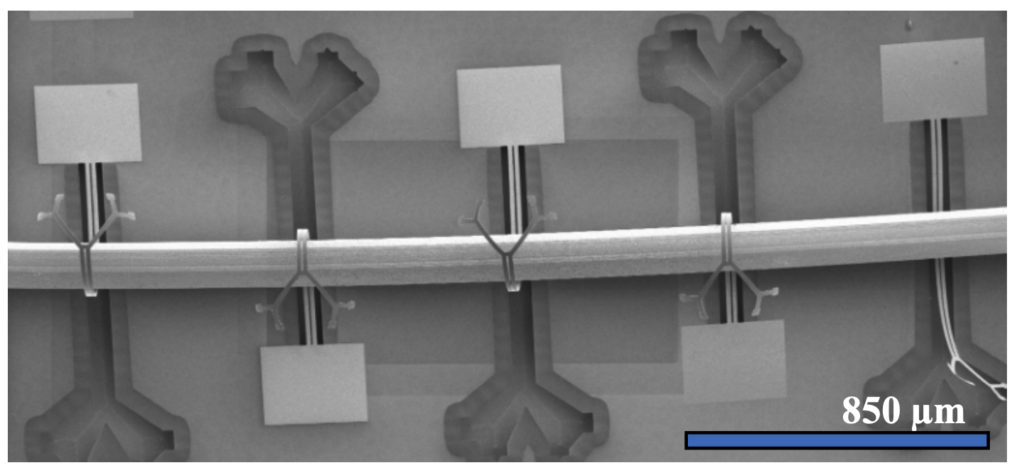

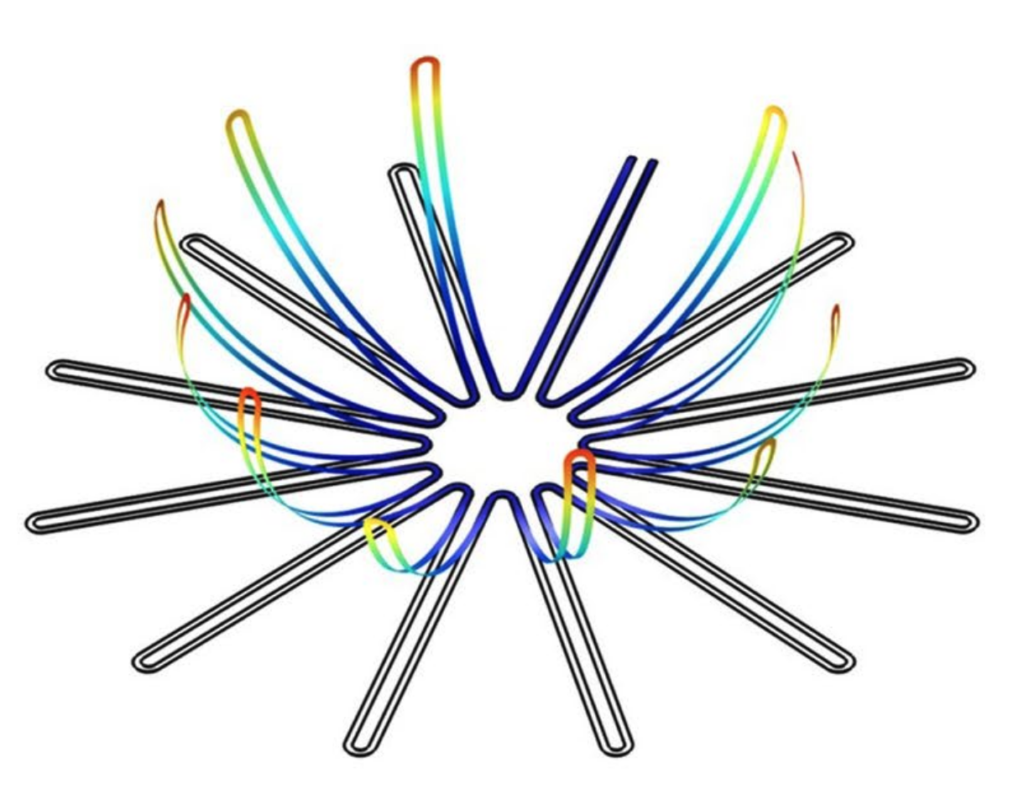

Left: Slow motion release using a heater trace, Right: real-time video of microhooks grasping a wire. The 200 micron (0.2 mm) diameter wire runs horizontally across the bottom of the right image.

To help our small sensors tap into power and send signals out, we have developed microhooks that grab onto wires. Grasping is triggered by an electric current that breaks polymer tethers at the ends of the hooks, allowing them to spring up into their preferred curly shape. Details are in our publication: