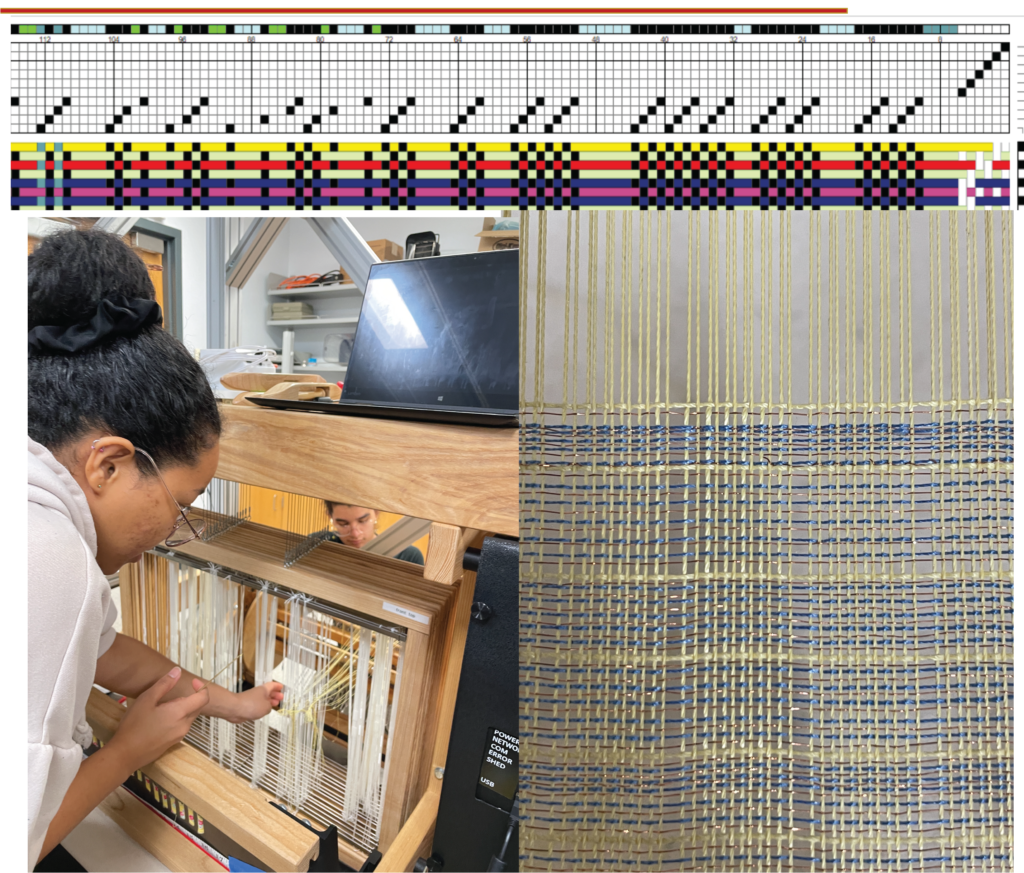

Our lab is thinking about how to connect flexible and stretchable electronic circuits together. Whether it’s a soft silicone stick-on “electronic tattoo” or a fabric based e-textile, no one wants to plug in a huge lumpy connector at the edge of the device. However, these circuits usually need connectors for power and communication. We are looking at how weaving can create binding sites to deliver power and signals to tiny sensor chips. This work is supported by National Science Foundation Award 2309482, “EAGER: Cut-and-Seam Manufacturing of Sensor Meshes for Perfusable Electronics,” which provided opportunities for 4 students to do research on fiber circuit assembly, seam tape fabrication and testing, and microfabrication in the lab this year.