Textbooks: 1. Course notes free from instructor. 2. Plastic Fantastic

I want a reminder near enrollment time/I have a question

Enrollment details:

-No prerequisites for Speed Masters and PhD students

-Undergraduates interested in taking a 600-level course must have permission from their department chair; your academic counselor can help get that request started.

-If outside the ECE dept, please discuss with your academic counselor for assistance enrolling. The instructor is happy for non ECE Masters/PhD students to enroll unless the course interferes with your other degree requirements. Your academic counselor can check it for you.

-Non-ECE students interested in taking the course specifically as an MEng technical elective must have it approved by their department. Again, your academic counselor can get that request started.

Detailed course description and schedule:

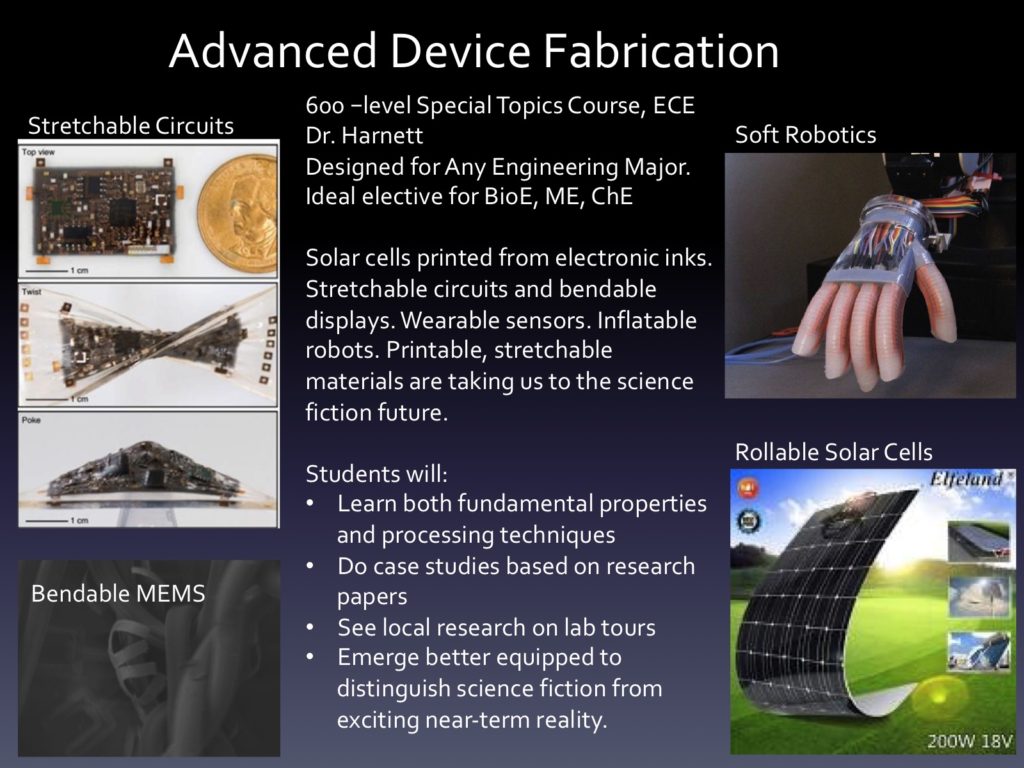

Solar cells printed from electronic inks. Stretchable circuits and bendable displays. Wearable sensors. 3D printed biological tissues. Fibers that sense and actuate. Soft inflatable robots. These “extreme machines” show how printable, soft, and stretchable materials are taking us to the science fiction future. How can we make devices with them?

Compared to the 70+ year history of semiconductor electronics, these soft material systems are young. Advances in semiconductors gave us computers. Now, low-cost computers make it possible to 3D print, pattern, and assemble soft materials with new functions. New forms of materials include nanoparticle inks that conduct electricity and emit light. Tissue engineers now use soft 3D printable biocompatible materials to host biological cells and sculpt them into organs. Conventional semiconductors recently joined the soft materials family in ultrathin forms that are flexible and even stretchable.

Students will use course notes to review the fundamental properties of soft materials, and do selected readings to define processing-based limits. Through homework assignments and case studies, the class will determine how to align, combine, and characterize soft materials for specific applications. Students will tour labs in ECE, ChE and BioE, and then do individual reports related to a current or their own possible future research topic.

Not planning on a research path? Leap ahead in your career with next-generation fabrication methods, and emerge better equipped to distinguish science fiction from exciting near-term reality.

Week 1

Soft Materials Families:

Nanoparticle/Fiber/Polymer/Thin films —

Our course modules are organized in the order of this material family tree.

Scaling plots. Fundamentals and homework

Week 2

Nanoparticles:

Fundamentals and homework – Nanoparticle self assembly forces

Nanoparticle behavior in solutions, on surfaces and when drying

Making silver colloid ink

Week 3

Nanoparticle processing:

Solution processing: Inkjetting, spraying. Optomec and Dimatix

Semiconductor nanoparticle ink/Solar cell lab

Week 4

Mechanics:

What does ‘soft’ mean: it stretches or bends a ‘lot’ for a ‘small’ force

Fluid flow (need this later when discussing hydrogel printing)

Capillary forces & other forces in soft materials: fundamentals and homework

Soft to hard interface problem

Week 5

Soft Robotics:

Elastomers, what are they

Sacrificial materials, what and why

Applications and homework

Week 6

Fibers:

Mechanical properties of fibers

Extrusion

Liquid crystal elastomer actuator fibers, coiled polymer actuator fibers

Polymers + Fibers: a composite soft material

Fiber reinforced soft robots: lab visit

Week 7

Optics:

Fiber optics

Optical properties of soft materials

Stretchable optical fibers

Quantum dots revisited (because of their optical properties)

Week 8

Gels:

Hydrogels, micelles

3D printing micro and macro objects from gels–Resolution limits homework

Biological applications overview. Tissue printing requirements for biocompatibility.

Gel printing tour (lab hydrogel printer & enzymes)

Week 9

Electronics:

Review concepts: conductivity, LEDs, transistors

Review what is already happening: Flexible circuit industry, anisotropic conductive films are commercial. Some are intrinsically stretchable (zebra connectors) others just bendable. Liquid metals are still cutting-edge.

PEDOT, organic semiconductor inks (and other materials) for flexible displays

Plastic Fantastic: hype vs reality.

Commercial products with organic semiconductors: lightweight, yet giant TVs

Week 10

Thin Films:

Conventional semiconductors as flexible materials: stretchable electronics from thin films

What are thin films? What about graphene?

What makes a thin film “stretchable?” Fundamentals and homework

Week 11

Case Studies:

Students present case studies from assigned journal papers. Students can develop final presentations on this, or a different topic.

Week 12

Compliant microlectromechanical systems (MEMS):

MEMS as soft materials: Compliant MEMS membranes and structures

MEMS crash course, fundamentals and homework

MEMS lab tour: Compliant MEMS fabric grippers

Week 13

Advanced topics: soft flexible electrode arrays for brain/nerve/skin interaction

Advanced topics: soft paper and thread-based chemical sensors

Advanced topics: soft robotic skins

Week 14

Advanced topics: integrating soft materials into wearable systems

Advanced topics: wearability/washability/user acceptance

Advanced topics: soft materials for energy harvesting

Week 15

Individual presentations.