Design it online without installing anything

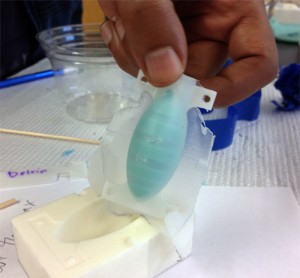

Here is a 3D printable inflatable actuator dipped in silicone to make it airtight. This could be an alternative to casting for making soft actuators.

There are some annoying things about designing sensors and actuators, and sharing those designs. One big problem is getting everyone on a project set up with the right software to create, share and modify designs. When I have a mac and you have a pc, and the software costs a lot and files from new versions are incompatible with old ones, everything gets stuck and we have not even begun talking about how the design works.

In that spirit, here is our parametric designer for the telescoping cone actuators. In 2015 it works in Safari, but you have to enable WebGL. Slide some sliders, get a stl file, and your browser is doing all the work except printing it and dipping it in silicone. If you print it, you’ll have to chip out the support material to separate the cones. Thanks to Chris Kimmer for the test prints.

Continue reading “Design it online without installing anything”

Summer Student Project: Inflatable Actuators

We had a physics student from Berea College, Fidel Tewolde, in our lab during summer 2013. His project was to create inflatable silicone actuators to drive our bistable beams from one state to another. With a bistable skeleton, you might be able to save a considerable amount of power by shutting off the air pressure when the actuator has flipped! Thanks to a great tutorial on printing your own robot, Fidel was able to get going fast. See the rest of this post for more photos.

Continue reading “Summer Student Project: Inflatable Actuators”

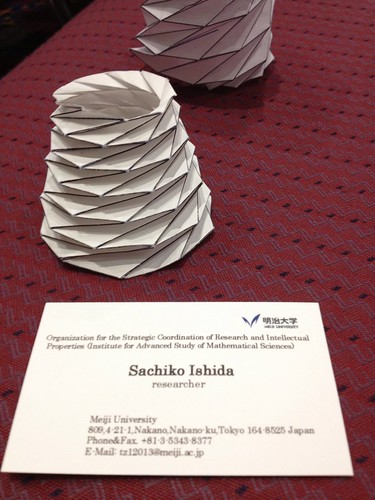

Symposium on Origami-Based Engineering Design, Portland OR Aug 4-7

Origami is showing up big time in deployable structures, as well as at the microscale. This symposium within the 2013 ASME conference in Portland was unusual both for the attendees’ various backgrounds, from math to aerospace to micro/nano engineering AND the amazing folded paper demos people brought along. “Flat folding” gets into some deep mathematics, but is necessary for international attendees to get all their demos on the plane, such as this twisting cylinder by Sachiko Ishida. Here is our paper:

UPDATE: Here are the slides from our presentation, including a movie of bistable tiles forming a bowl shape.

Animation of a microdevice with two stable configurations

This video shows how two curved beams can interact to produce bistability. The green and blue beams are constrained so that their tips stay a fixed distance apart, shown by the red dotted lines. (In practice, the red line would be another beam made out of the same material.) The green and blue beams also have a preferred radius of curvature that minimizes their stored energy. We adjust the preferred radius of the blue beam by changing the temperature. However, the constraint makes it impossible for the green beam to take on the preferred radius of curvature at the same time. Instead, there are two mirror-image energy-minimizing states. In the video, the beams are drawn thicker when in the energy-minimizing state; at the same time, the slider on the energy plot is at a local minimum.