Nanoparticles are boring SQUARE HOLES in our silicon wafers!

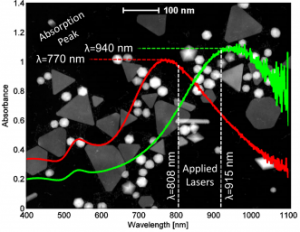

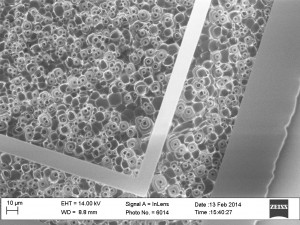

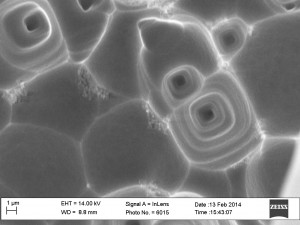

The gold nanoplates from the O’Toole group enhance the etch rate in our usual silicon-etching process. Mysterious square pores appear when nanoparticles are present on the silicon. Others have made conical nanopores in a different etch chemistry and with different gold nanoparticles, and used them as channels for studying ion transport. But ours are coming out square. There is a well known process to etch square holes in silicon using potassium hydroxide (KOH) or similar etchants, but you have to define the edges of the holes first. At a much larger scale, it’s possible to make square holes using a drill!