Our lab has a new paper out in collaboration with the Berfield group about a windowpane-shaped microstructure that has two stable shapes. Tom Lucas (who graduated with a Ph.D. from our group in 2014) and Jaz pointed a heat gun at the MEMS devices one day, trying to flatten them by thermal expansion. This led to …

Category Archives: Bistable

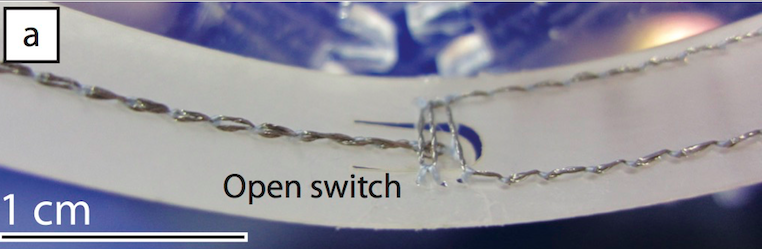

Stringing some wires

We have been dealing with bistable structures across different size scales. A common question is, how can we detect their state electronically. This project uses machine-sewable conductive thread to add an electronic switch to bendable compliant beams in a cm-scale structure. The beam material is 0.125 mm thick plastic film: thick enough to have some “snap” (video …

Vibrating beams are like dartboards

The upper plot in this video shows the “basins of attraction” for a bistable compressed beam as you bend its support angle from flat (0 degrees) to about 18 degrees. This beam is about 4% too large to fit in its assigned area, so the center pops up or down. From our earlier work we …

Summer Student Project: Inflatable Actuators

We had a physics student from Berea College, Fidel Tewolde, in our lab during summer 2013. His project was to create inflatable silicone actuators to drive our bistable beams from one state to another. With a bistable skeleton, you might be able to save a considerable amount of power by shutting off the air pressure …

Continue reading “Summer Student Project: Inflatable Actuators”

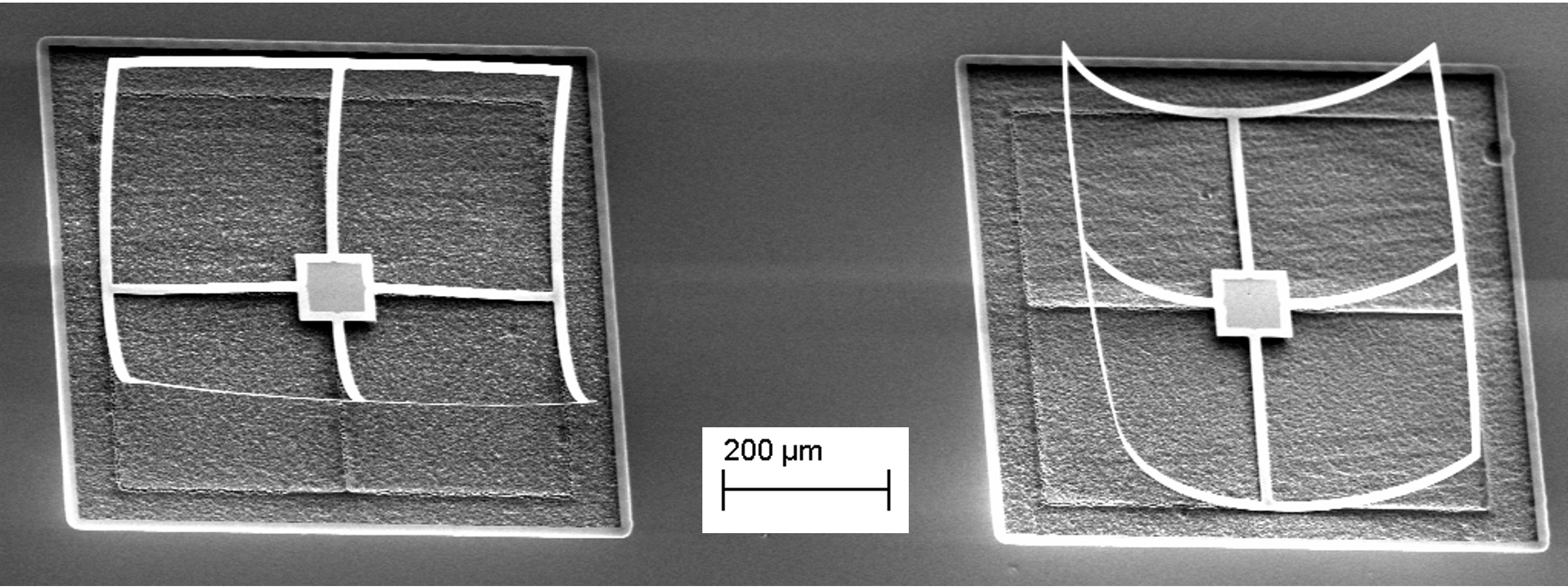

Animation of a microdevice with two stable configurations

This video shows how two curved beams can interact to produce bistability. The green and blue beams are constrained so that their tips stay a fixed distance apart, shown by the red dotted lines. (In practice, the red line would be another beam made out of the same material.) The green and blue beams also …

Continue reading “Animation of a microdevice with two stable configurations”