Trying out a new poster-hosting site, so here is a somewhat recent one from our latest graduate. Tom Lucas’ poster won the “best poster” award at the 2013 KIEC conference!

Vibrating beams are like dartboards

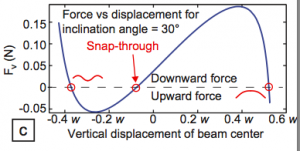

The upper plot in this video shows the “basins of attraction” for a bistable compressed beam as you bend its support angle from flat (0 degrees) to about 18 degrees. This beam is about 4% too large to fit in its assigned area, so the center pops up or down. From our earlier work we know that beams prefer to pop in the same direction as the supporting substrate, and we have the potential energy function that describes this behavior more quantitatively. It’s the lower plot.

When a beam is dropped into “phase space” (a plot of velocity vs position of the beam center) it will coast to one of the two minimal energy positions. The red spiral shape is the region of phase space corresponding to the higher energy state, and it shrinks as the substrate bends. When the high-energy basin of attraction goes to zero area, the beam snaps to the low-energy state if it wasn’t there already. We are looking at the area of the spiral as a way to measure the curvature of the underlying substrate through the statistics of repeated experiments. This is a “dartboard” style experiment; a smaller target should receive fewer hits than a larger one.

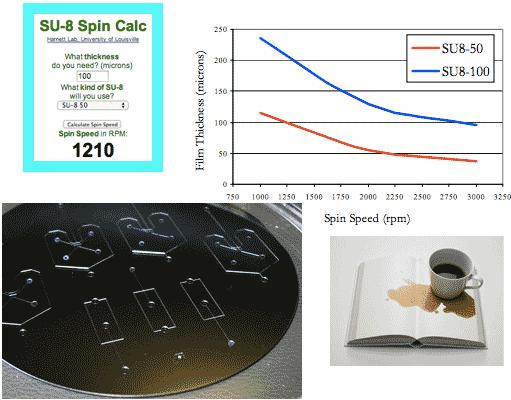

Calculate your spin speed for SU-8 photoresist

Dragging an ancient, stained cleanroom notebook around (NO DRINKING COFFEE IN THE LAB!) or constantly digging up the MicroChem SU-8 datasheets to calculate your SU-8 spin speed? Check out our SU-8 Spin Calc.

SU-8 is a thick photoresist often used for making molds for microfluidic devices. Since the photoresist is part of the final structure, its thickness is very important, and thickness is a function of spin speed. It goes approximately as the inverse square root of spin speed, so we can calculate the spin speed for a given thickness using a few known data points. Thickness will depend on a few other variables such as age of your resist bottle (has the solvent evaporated?) so be sure to do a test spin!

Makerspace Co-op featured at NSF website

Our co-op Makership program was just featured at the National Science Foundation (NSF) website in an article discussing NSF’s involvement with the “Maker” movement. During 2012-2013, in a collaboration with Dr. Thomas Tretter in the College of Education and Human Development, we had 9 University of Louisville undergraduate engineering students carry out their semester-long Co-op internships at LVL1, Louisville’s own hackerspace. Students carried out their own individual projects and were interviewed during the semester. We were interested in their transition from lab and coursework to independent work. They got weekly guidance from a mentor but –like many graduate students–were in charge of their own day-by-day activities, and had to figure out what to learn to get to the next step. A common theme emerged: build a prototype quickly, learn from it, scrap it and start over!

Paper published: beams on flexible supports

Here is our analysis of bistable beams on flexible supports, written up. The take-home message is that when the support is flat, the beam has two states, up or down. But when you bend the support too far, the beam is only stable in one of the positions. Connect up a readout system to these beams, and you have a kind of “binary” curvature sensor.