Where is that thing bending? PhD student Paul Bupe has developed a prototyping system for determining where robots and other flexible structures are changing curvature. The OptiGap concept uses soft plastic 3d printing filaments as waveguides with gaps that let light out when bent. Not only is the system low cost and customizable on the fly, but it gets multiple location information out of a single optical intensity sensor, and provides a training routine so your system knows how to interpret the incoming optical signal. Paper here:

Adaptive Grasping Control

Ph.D. student Michael Han has further improved the optoelectronic control method with an adaptive control algorithm, enabling robotic grippers to hold on to objects without crushing them even under changing conditions. This video also shows a little more detail about the soft optical sensor’s construction. Paper:

Sensor stops slipping

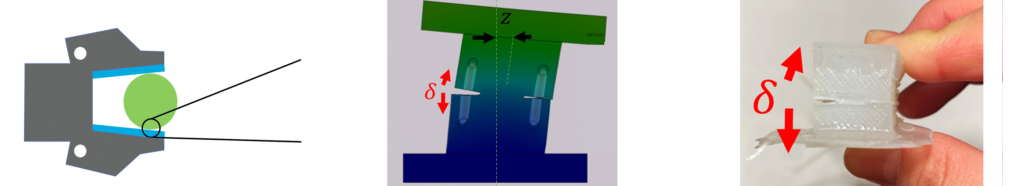

Ph.D. student Michael Han has developed a new optoelectronic tactile sensor that enables robots to better emulate the grasping abilities of the human hand. The sensor, described in “Soft, All-Polymer Optoelectronic Tactile Sensor for Stick-Slip Detection,” combines a skin-like soft silicone material with a bristle friction model to provide not only normal force information, but also lateral force information generated by stick-slip processes.

This soft optical design allows the sensor to detect stick-slip events, a phenomenon that occurs when an object starts to slip out of a robot’s grasp. By detecting stick-slip events in real-time, the sensor can help a robotic gripper apply sufficient force to grasp objects without slipping. In addition, the sensor is capable of measuring normal forces up to 5 N, making it a versatile tool for robot grasping control.

The sensor is made entirely of polymer materials, making it soft and flexible like human skin. This allows it to easily conform to the shape of different objects, providing a more natural and accurate tactile sensing experience for robots. By enabling robots to more accurately sense and respond to their environment, we are one step closer to creating robots that can perform tasks with the same level of dexterity as humans. We continue to work on improving the sensor and exploring new applications for it in fields such as manufacturing, healthcare, and more.

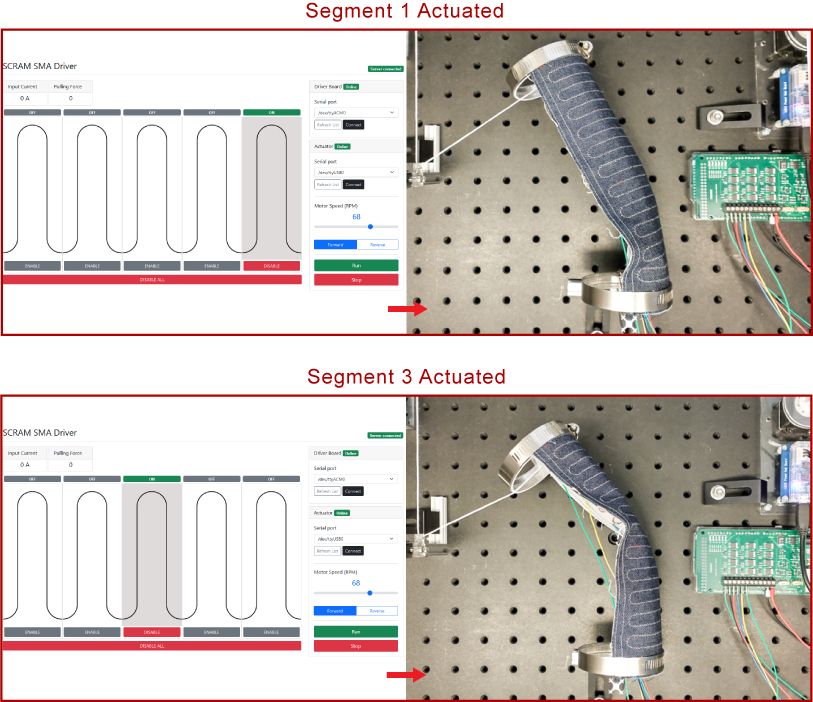

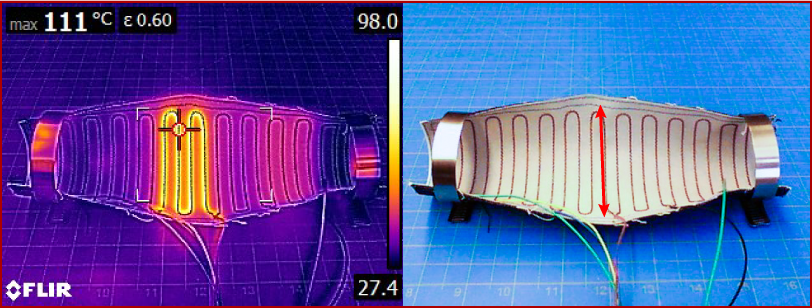

Electronically Reconfigurable Virtual Joints by Shape Memory Alloy-Induced Buckling of Curved Sheets

In our latest paper we leveraged the anisotropic properties of curved sheets to create reconfigurable joints. Imagine a flat material like a thin piece of paper. This piece of paper can be stiffened by curving it along a single axis into a U-shape. In this case the anisotropic property is that it resists bending along the curve due to increased stiffness in the remaining axis. This stiffness can be reduced by creating a small change in shape along the curve such as creating a temporary flat spot or crease, which results in a reduced stiffness at that point meaning the curved paper can bend there.

We used shape-memory alloy (SMA) wire sewn into some denim and stiff plastic using tailored wire placement to form a “crease” when energized which creates a flexure hinge, allowing the structure to bend. Since we are able to electronically control where this crease is formed we can create a hinge up and down the structure, meaning we can reconfigure the location of the joint.

Here’s the proceeding:

This project is part of the SCRAM consortium, supported by NSF award 1935324.

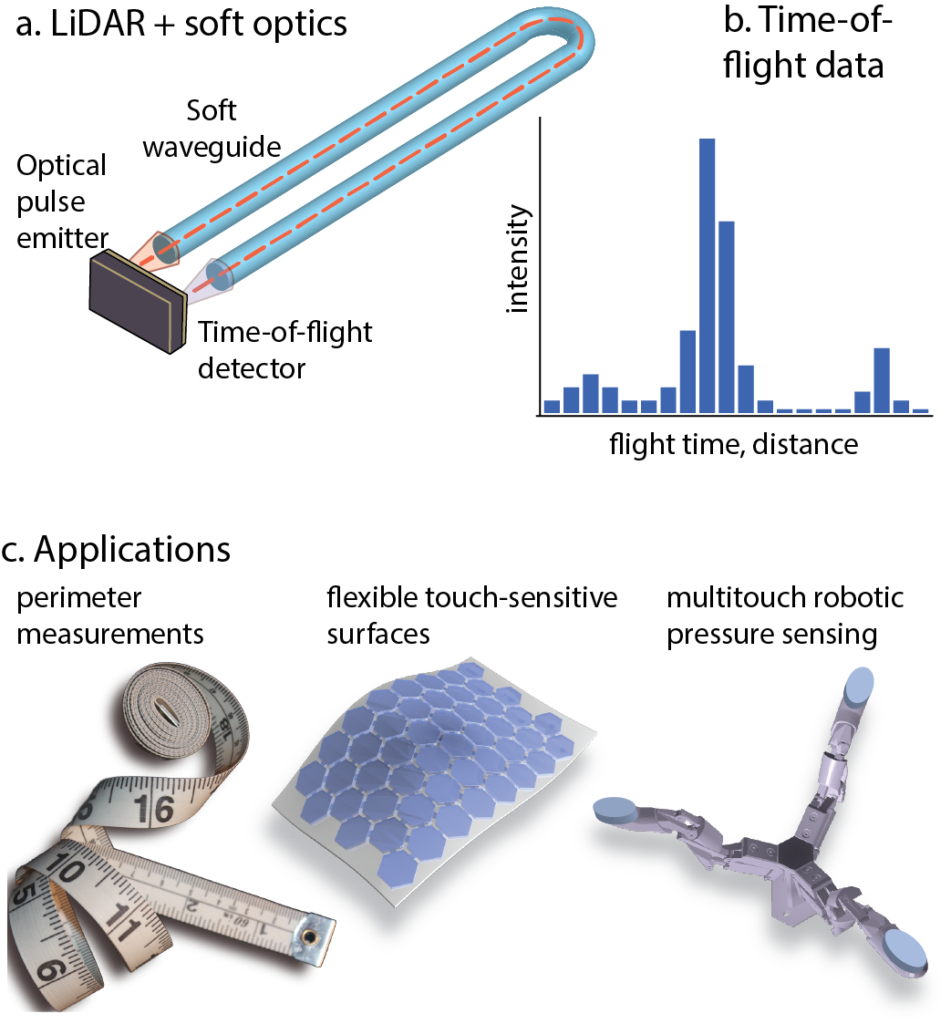

Sensing pressure at the speed of light

In our latest paper, an optical pulse travels through a branched waveguide network. A ranging sensor made for consumer electronics is put to work measuring the arrival time distribution of the pulse after it splits and travels through branches with three different lengths. Rubber “switches” squeeze down on each branch when pressure is applied. This setup means a single optical sensor can monitor multiple pressure points in a system. Here, Dr. George Lin uses the setup to keep track of an object rolling around on a plate. Since the materials in the sensors are soft polymers, including the waveguide material, it’s a good match for soft robotics. It also works underwater.

Our low-level time-of-flight sensor reading code and sample data are available online.