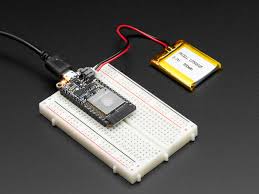

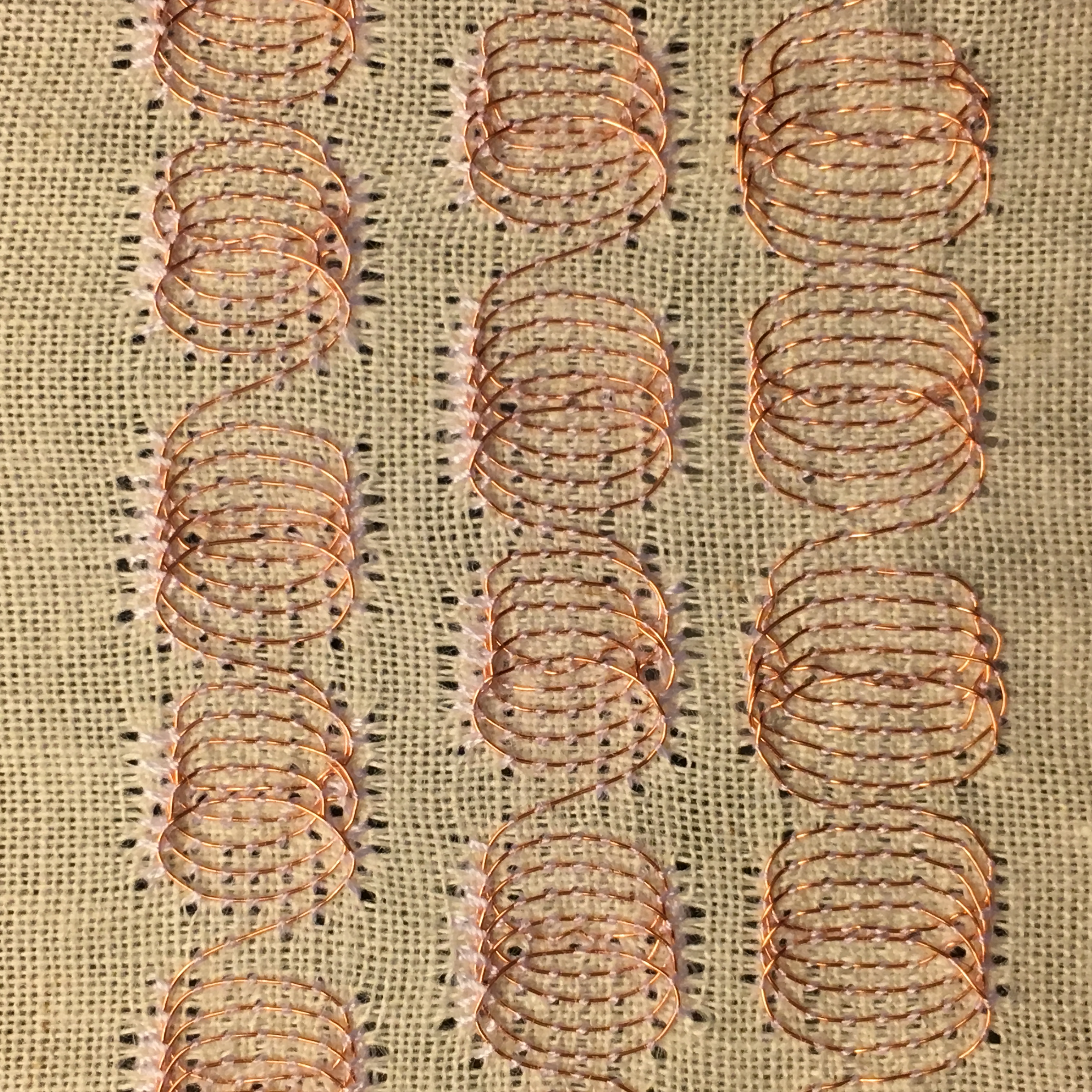

This semester’s lab-affiliated Capstone team is busy testing the wireless wearable accelerometers they’ve built. Our Capstone course is a semester of senior year and it’s usually the last project students do for course credit. The big picture for Team 9 is a system to measure training intensity, with some great guidance from the Athletics department. For now, however, this means engineering students are running and sometimes leaping down the hall carrying wireless breadboards. Besides circuits, they’re setting up a data server and handling streaming data. Can they identify jumps and count jumps per minute, for 20 athletes at once? Time will tell!

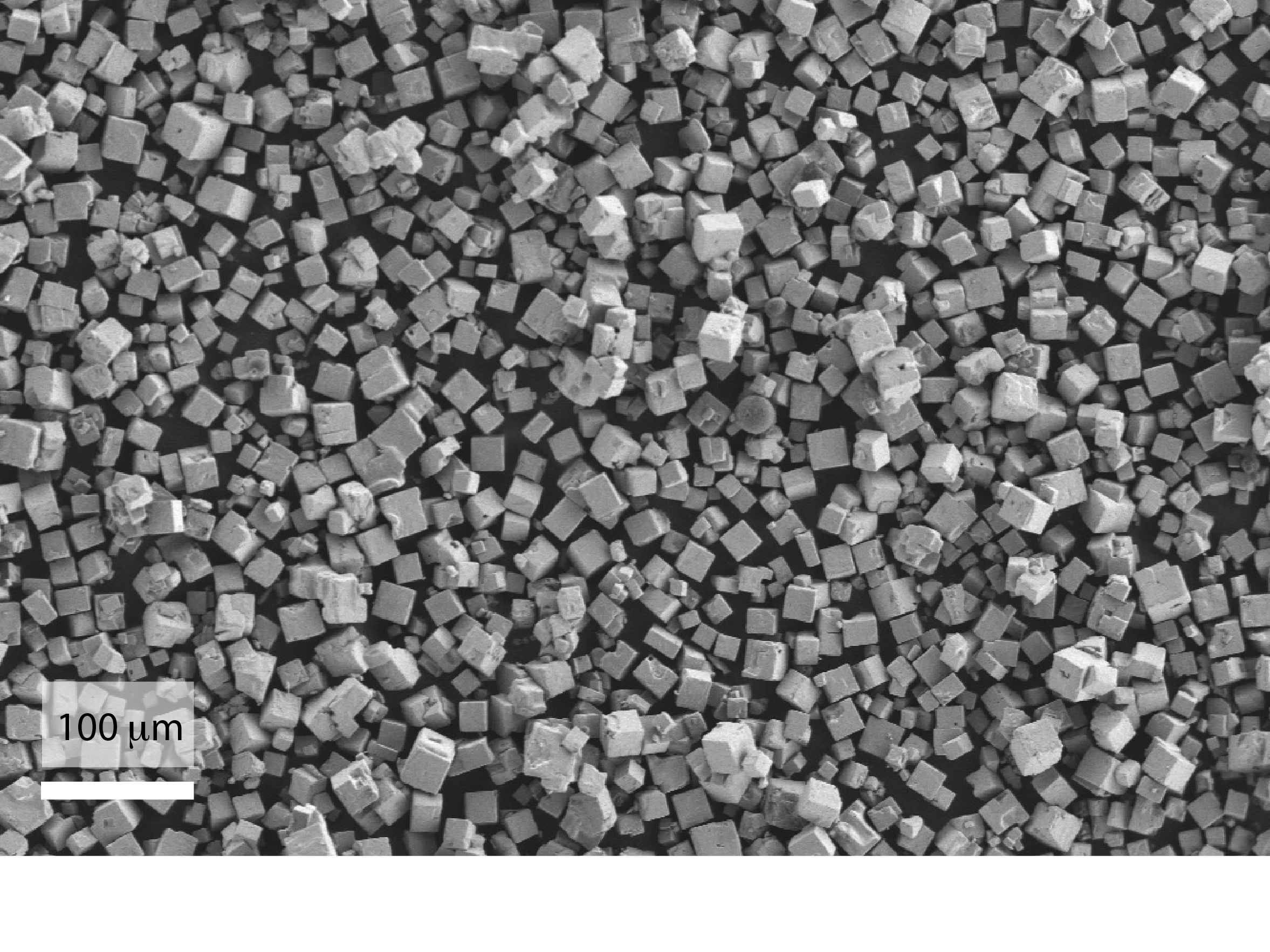

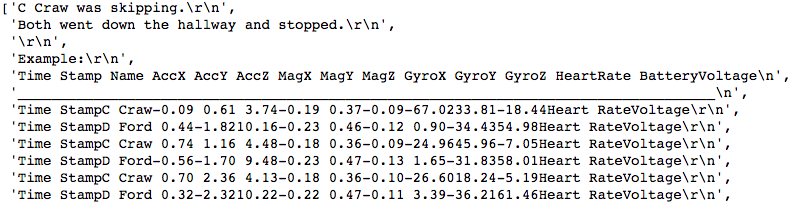

Their task is to build a system that collects raw data from wearable sensors. Here is interleaved data from two students:

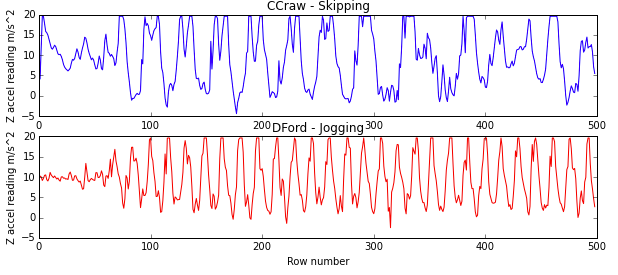

This wall of data can be turned into a plot of vertical acceleration, separated out for each student. Can you tell who is skipping vs jogging? Let’s pit one student against another. Well, these two students seemed to take about the same time to get up to speed. Next, they’re working on finding features in the data such as jumping height, number of hops, and hop rate.

And of course Team 9 is looking at ways to conserve battery power. Even though the battery is rechargeable, it needs to last through a practice. A “charger doctor” for checking on USB device performance is an easy way to keep an eye on system power consumption.