Here are the group’s presentations at the Materials Research Society fall meeting in Boston last week. One talk and 3 late-night posters; the abstracts are available online here. The common theme was fibers as sensors, actuators and structural components.

In this work with the Kate group at U of Louisville, we modified our stretchable optical fibers’ light transmission by changing the extrusion speed.

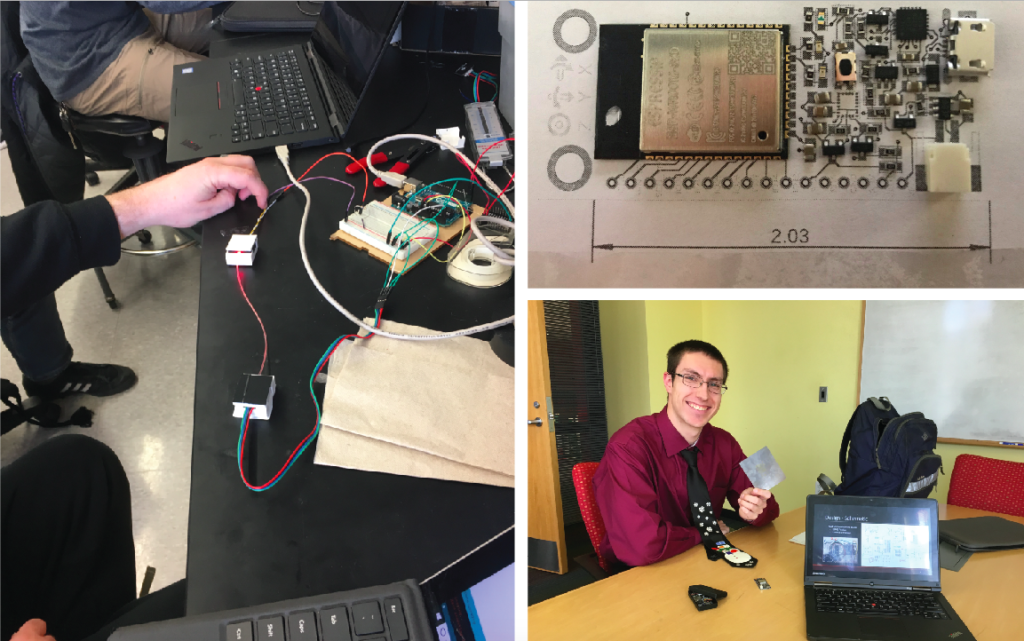

Poster time: Here is our embroidered linear motor. Most of this poster is captured in a journal article that came out shortly before the conference.

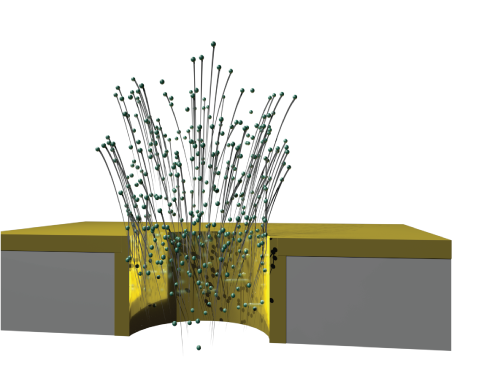

Next up was our collaboration with the Cai group at UCSD, using liquid crystal elastomer fibers to create active surfaces such as this one, with flaps that open under a heat lamp (speeded up 10x)

And on the last night, our summer REU student Canisha Ternival’s work on MEMS fiber grippers– check out the crab claw design grabbing on to fabric in the lower right. We are looking at grippers to attach sensors and actuators to porous surfaces.

Thanks to all summer 2018 collaborators for getting these projects off the ground.