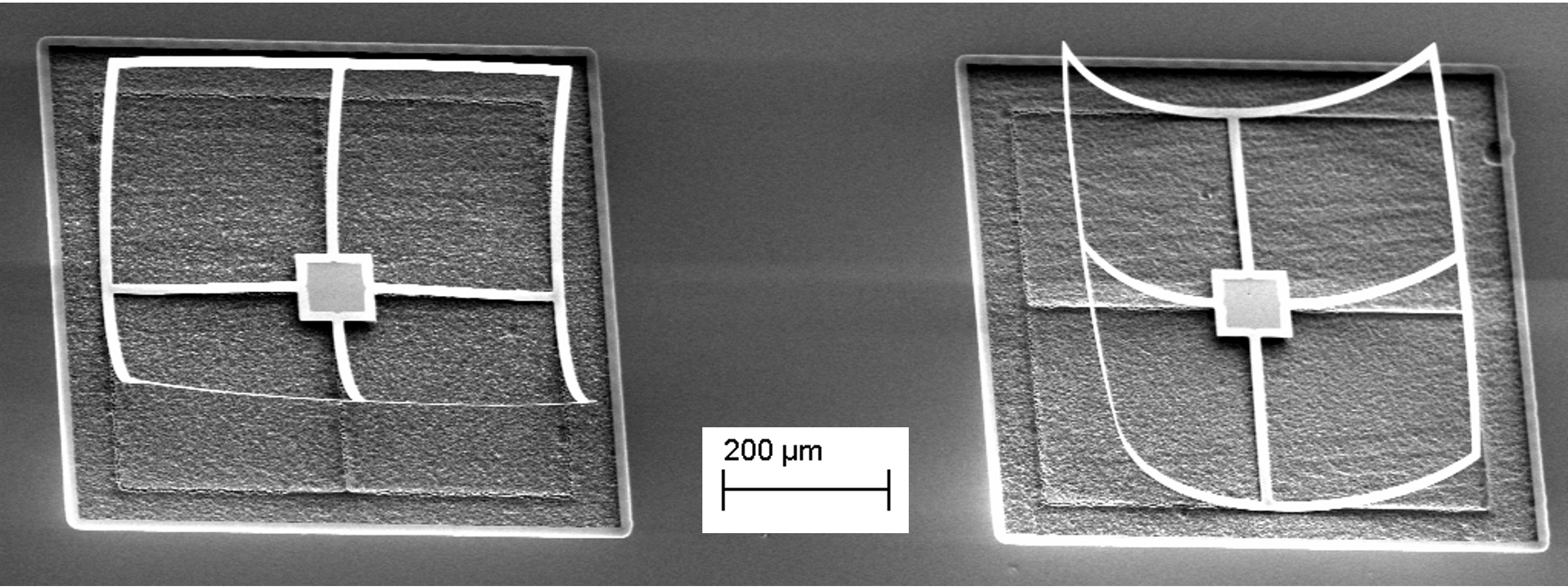

Our lab has a new paper out in collaboration with the Berfield group about a windowpane-shaped microstructure that has two stable shapes. Tom Lucas (who graduated with a Ph.D. from our group in 2014) and Jaz pointed a heat gun at the MEMS devices one day, trying to flatten them by thermal expansion. This led to the discovery that the structure would flip from one to the other by aiming compressed air at it. Thanks to these experiments and Dan Porter’s model, we know that larger devices flip at lower airflow velocities.

The best applications for these bistable microelectromechanical (MEMS) devices are situations where power is limited, because they don’t need power to hold their shape. For this reason, bistable devices are candidates for radiofrequency (RF) switches in mobile phone applications, where it’s important to conserve the battery. The difference between this windowpane device and most other bistable devices is that the windowpane curls out of the plane of the silicon wafer due to residual stress. Usually MEMS makers try to cancel out residual stress, which is the enemy of predictable in-plane motion. Also different: the device in this paper would probably still be bistable if completely removed from the wafer.

The windowpane-shaped device in the paper could be used as a passive marker for peak airflows. Our group has also switched bistable devices using electric currents. With electrical contacts, it could potentially make a low-power electronic switch using significantly less wafer area than a planar device.