This semester we have four students working for independent study credit.

There are two GE Edison students working on low-power Internet of Things applications:

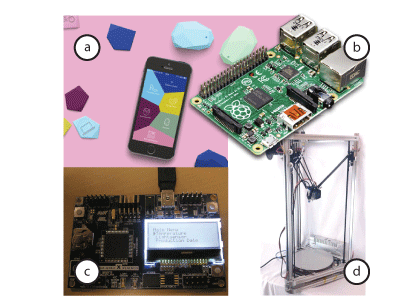

Juan Espinosa is using Estimote Bluetooth Low Energy beacons (a) to develop a location-based iOS app, with the goal of setting an alarm when an item (or person) wanders off.

Laura Artunduaga is investigating MQTT for sending sensor data to a database over Wi-Fi, using a Raspberry Pi (b). She attended the recent Wi-Fi workshop at LVL1 and is looking at Adafruit as a place to store sensor data for her experiments. She is also evaluating how the low-power MQTT method applies to secure health sensor data.

Troy Kremer, the ECE 412 (Embedded Systems) TA, continues his work on serial interfacing for the A3BU microcontroller (c) that we use in class.

And Amer Beharic is investigating 3D printing on soft materials, and is also putting together a delta 3D printer (d). The most appealing feature of the delta printer for our group is that the printed object does not have to move during printing. This means you could potentially print on a giant roll of material, one section at a time.