Our tutorial is up at the Soft Robotics Toolkit website. It covers how to use an embroidery machine to add a patterned fiber layer to a 3D print, a circuit board, or a thin laser-cut part. It also describes how to use a 3D printed template for installing fibers that are too thick for the embroidery machine to handle. There’s a link to the Inkscape plugin for aligning patterns, plus some nifty alignment pegs Brian Wagner invented if you would rather laser-cut your template than do a large-area 3D print.

Building a lab around an enzyme

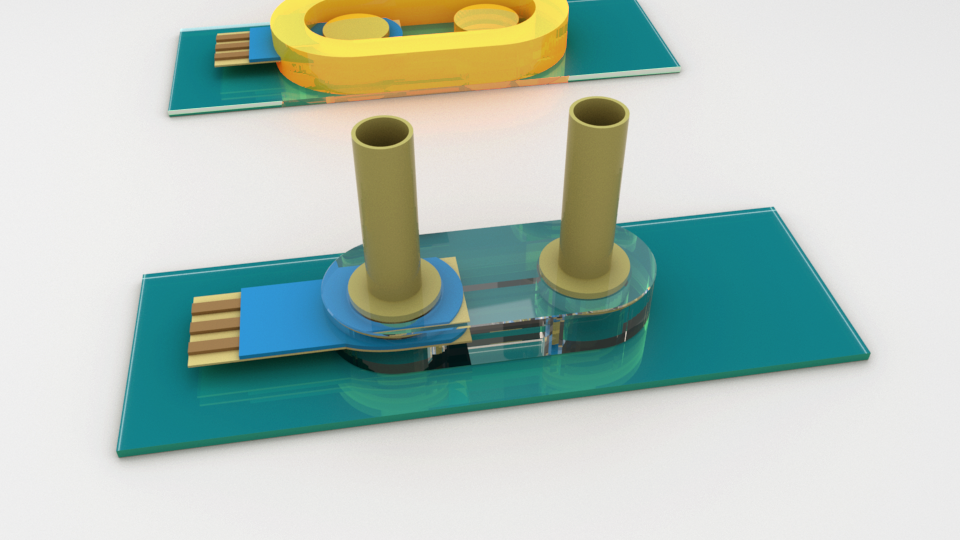

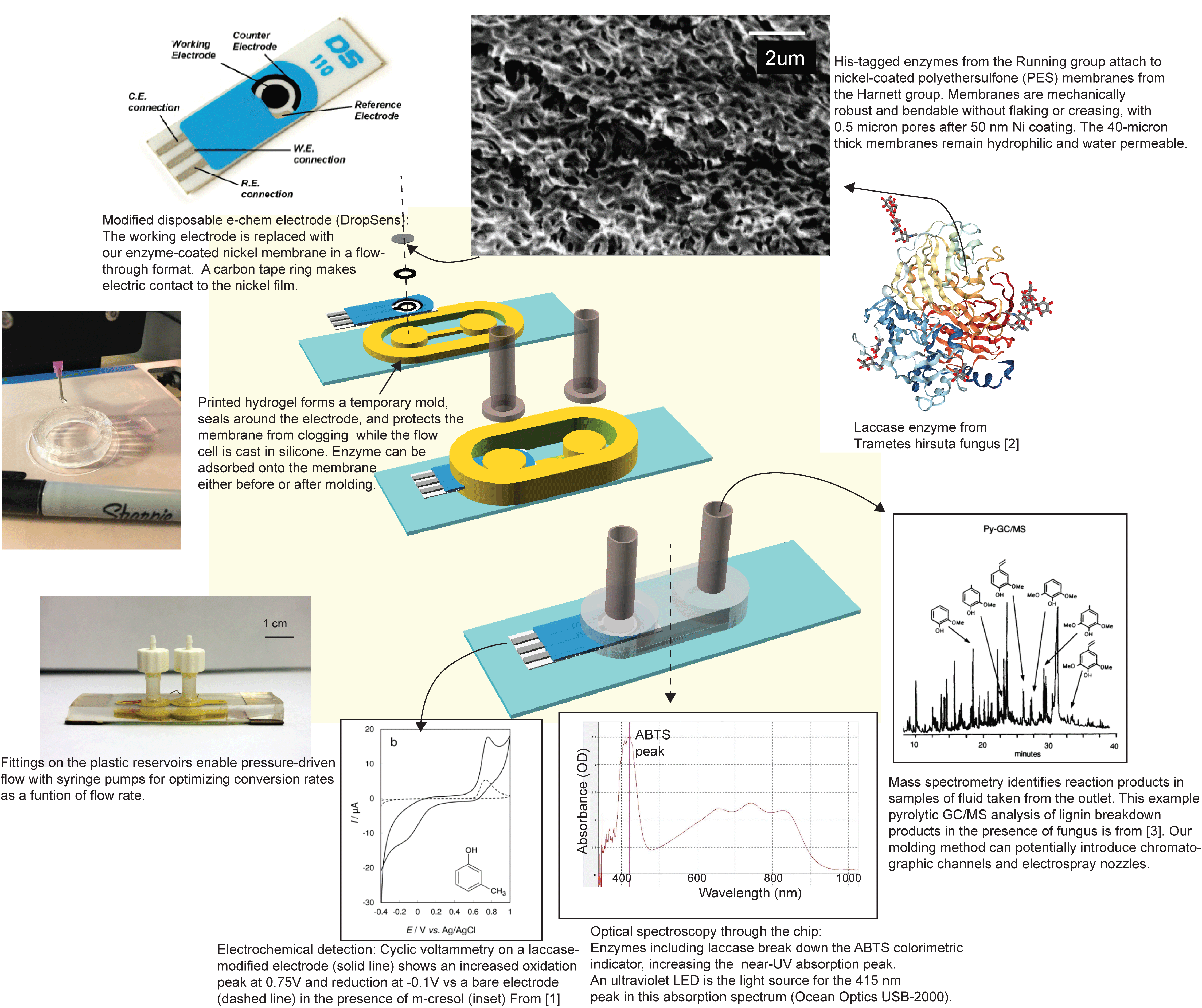

Shaf has been putting enzymes to work in our part of the EPSCoR project, “Powering the Kentucky Bioeconomy for a Sustainable Future.” His goal is to quickly measure the activity of tiny amounts of enzymes supported on membranes. Membranes covered with enzymes can convert one type of chemical to another at room temperature–but it’s unclear which natural or engineered enzymes are the best for a given application. We just have to test them. We’re using hydrogel printing as a gentle method to combine enzyme-coated membranes, electrochemical detection electrodes, and paths for fluid flow and light transmission in a small, disposable package that can measure the productivity of a single enzyme variant. That’s a lot. Good thing we have collaborators (Dr. Anne-Frances Miller at the University of Kentucky, Dr. Mark Running and Dr. Gautam Gupta at the University of Louisville, and students). Their expertise means Shaf is able to get electrochemical and optical detection started on the benchtop, using chemicals that change their conductivity or color when the enzyme acts on them. Meanwhile he’s discovering the best settings to keep the hydrogel printer happy.

[1] Sýs, Milan, et al. “Electrochemical Study of Trametes Versicolor Laccase Compatibility to Different Polyphenolic Substrates.” Chemosensors 5.1 (2017): 9. APA

[2] RCSB Protein Data Bank ID 3FPX

[3] Martınez, A. T., S. Camarero, A. Gutiérrez, P. Bocchini, and G. C. Galletti. “Studies on wheat lignin degradation by Pleurotus species using analytical pyrolysis.” Journal of Analytical and Applied Pyrolysis 58 (2001): 401-411.

Flex time

Back on campus after sabbatical. My group is focused on soft, flexible materials including stretch fiber optics that sense motion, non-stretch fibers that constrain motion, and thin porous membranes that drive flows– featured in Jaz Beharic’s thesis. Yes, Jaz graduated this month. Shaf continues on the membrane project with a more biological focus: porous surfaces that support enzymes to break down lignin.

The stretchable fiber optics paper is published:

And here is a quick writeup about sensing muscle activity using these fibers.

http://www.advancedsciencenews.com/strain-sensors-stitch-sportswear/

we heard you liked fibers

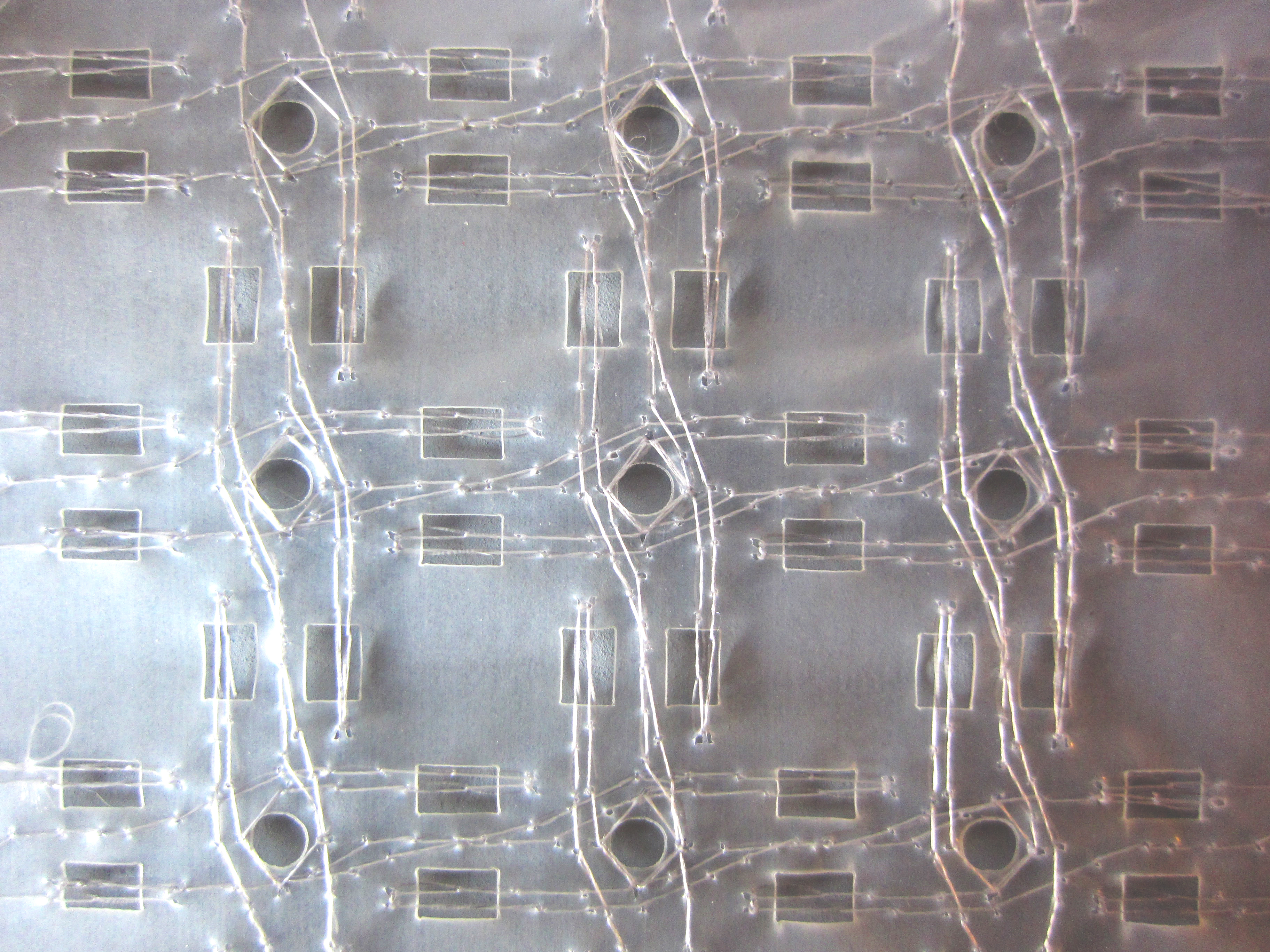

The Material Robotics workshop of the RSS conference at MIT was an intense day. We were energized by rapid-fire 3 minute presentations, mostly on soft and squishy robots, with breaks for posters. Here is our abstract and below is the poster from our lab, all about embedding functional fibers into materials that can sense and actuate. This work features Brian Wagner’s embroidery alignment plugin, which lets you write aligned PES embroidery files (for Brother machines) in the free vector drawing software Inkscape. With this environment, it is possible to draw shapes for laser cutting alongside the fiber paths that will be in the final structure.

Yes, the actual poster about fibers is made of fibers from Spoonflower on their Performance Knit fabric.

Seeing the light

This video shows a stretchable optical fiber that can report its own length. We have been developing sensor fibers that work with stretchable materials like athletic tape. The screen in the background shows the light intensity decreasing as the tape is stretched, and climbing back up as the tape relaxes to its original length. The intensity drop is caused mostly by the longer path length in a stretched piece of absorbing material, as shown in the animation here.

In applications where we sew the fibers onto another material, effects on the light intensity come from both the length change and from threads pushing into the fiber.

Some practical features of optical sensing compared to resistive electronic sensing is that all-polymer optical materials don’t corrode in a wet environment, cost less than metals, and don’t need a continuous conductive path. These properties will be handy when putting sensors on skin, creating disposable devices and making wearable sensors that might need to be washed.