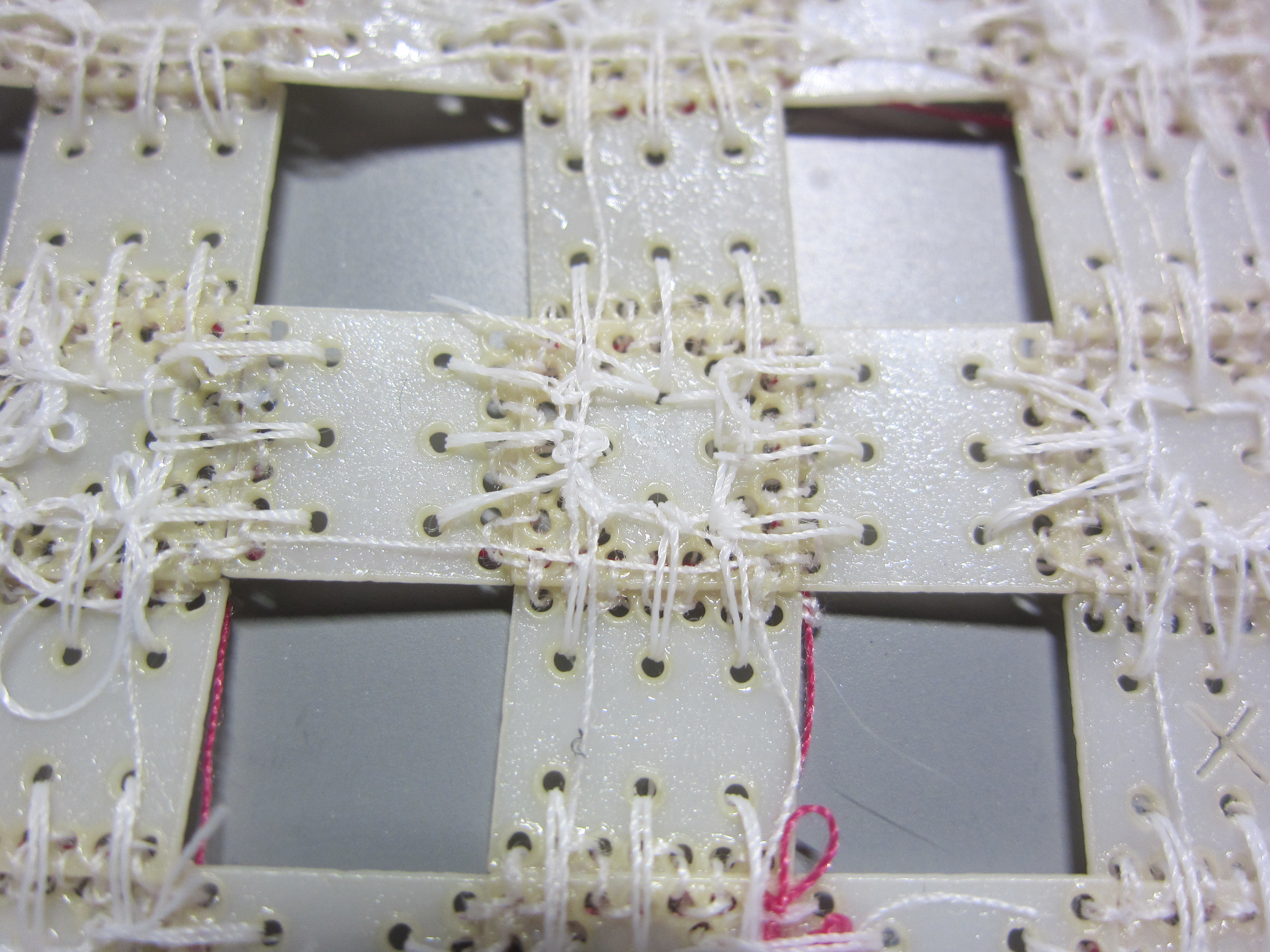

We are integrating fibers with 3D prints, laser-cut materials and other mechanical parts that aren’t traditionally mixed with soft materials. Here are some 1×1 cm laser-cut tiles sewn together with an embroidery machine to make flexible hinges. Shrinking thread locks the final design in a 3D shape. This consumer embroidery machine required some custom alignment software to line up the needle with the 0.7 …

Category Archives: Lab News

Charging Up

This video shows polymer cantilevers charging up in an electron microscope. At 2kV, charging is not a huge problem. But, at 5kV accelerating voltage, the cantilevers accumulate enough charge to get pulled down to the silicon substrate. From this video (sped up 6x), Jaz determined the need to use low accelerating voltages when trying to …

Tubular

This 3cm super soft silicone tube has a string inside, attached to the end. When the string is pulled 1cm you get multiple curls. Interestingly, the tube takes a very different path on the way back when the string is released! Tentacles and tendrils are a focus of biomimetic soft robotics, taking inspiration from structures …

A warped approach to circuits

What happens if you have to make a lot of crossovers on a circuit board? For example, here is a printed circuit board that connects pins 1 to 10 in a randomly chosen order. In this layout, finished by a person after the autorouter gave up, you have to drill 14 holes, spend time and …

Update: A blistering summer

Jeremy at FirstBuild pulled a couple of vacuum molds for the light diffuser on the Trilife cellular computing project. Here’s a video showing a softened thick PETG sheet forming over the triangular mold: Next you let it cool, then you tap it to knock it off, and then pull the mold down as in this …