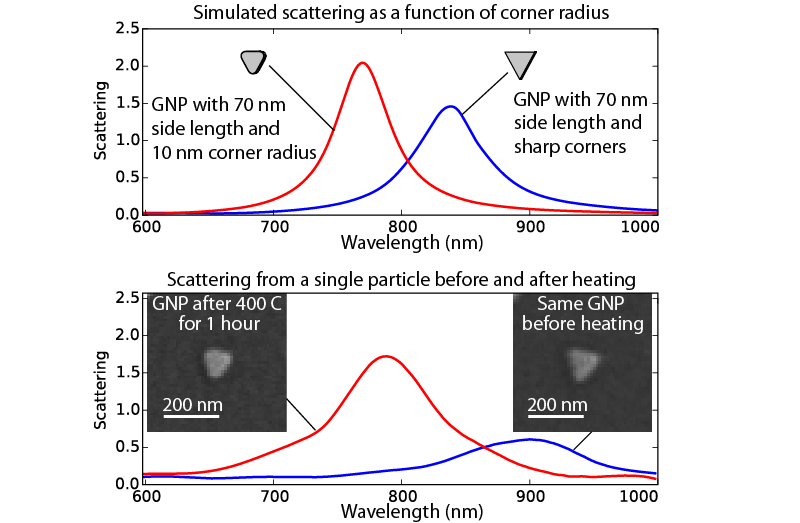

Our collaborative work on thermal processing of gold nanoplates with the O’Toole group (U of L Bioengineering) is accepted (update: published) at Materials Letters. We’ve used their triangular gold nanoplates to induce local heating of microelectromechanical (MEMS) structures with infrared lasers. The nanoplates are typically the first layer to go onto the MEMS wafer. In this paper, we show that temperatures in the 200-300 C range can shift the absorbance wavelength of the nanoplates by rounding the corners, far lower than the melting temperature of bulk gold (>1000 C). Thanks to careful mapping, Jaz and Kurtis were able to find the same tiny nanoplates (70 nm side lengths) before and after heating, in both electron and optical microscopes. Temperatures reach the 200-300 C range during MEMS processing unless you take care to use low-temperature materials and methods. So, when using gold nanoplates, either keep your cool or prepare for them to behave differently in the final device — absorbing shorter wavelengths than they started with.