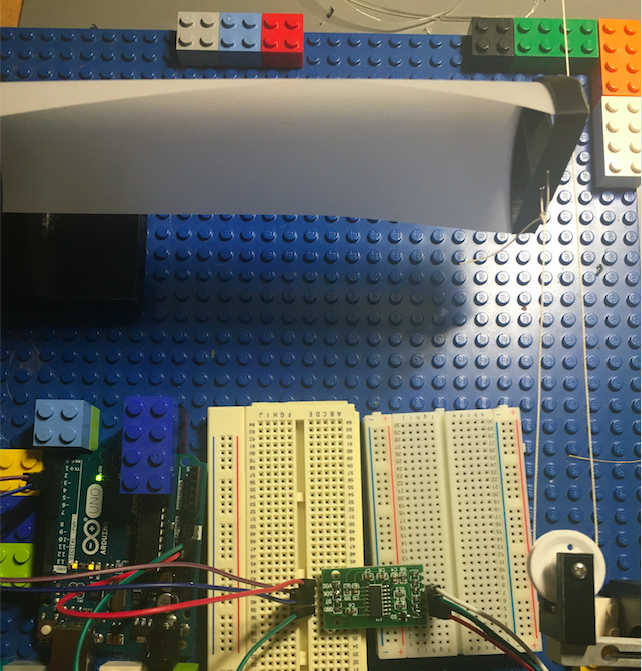

Remote work got standardized when Chris N. suggested we work with “bricks.” Plastic bricks emerged from boxes and tubs in different cities. He designed some 3D printed parts with pockets for bricks, so he could click them into place on this torque-vs-angle testing platform when the parts arrived from campus. No need to ship the heavy platform, because he also had some of those slab-like bases around.

Even now, with students near enough to campus to pick up and drop off items, the bricks are paying off because every photo has a scale bar. Good idea, Chris, one to keep handy for future collaborations at all levels!