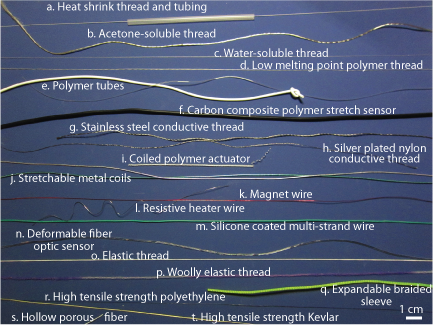

We continue to explore how fibers can get into the computer-controlled fabrication process. 3D printing takes the spotlight, but each year about 10x more sewing machines are sold in the US than desktop 3D printers worldwide. If we can combine some of their capabilities with 3D printing, a lot of exciting materials can join the party – whether or not you have industrial equipment. The picture below shows 20 kinds of engineered threads, fibers and wires that can be directly sewn (all the ones with “thread” in the name) or captured under sewn threads (generally the thicker, softer fibers and the wires). Thermally actuated threads that can’t tolerate high temperatures, or materials like flame-smoothed fishing line that require high temperature processing, are challenging to 3D print using the most popular “hot glue” style printers. Structured fibers like braids are much faster to build with textile machinery than 3D printing, while hollow porous fibers for water filtration and the coiled polymer actuator in the video above rely on chemistry or external forces that aren’t yet available at the desktop 3D printer nozzle.