Spring 2023 Course

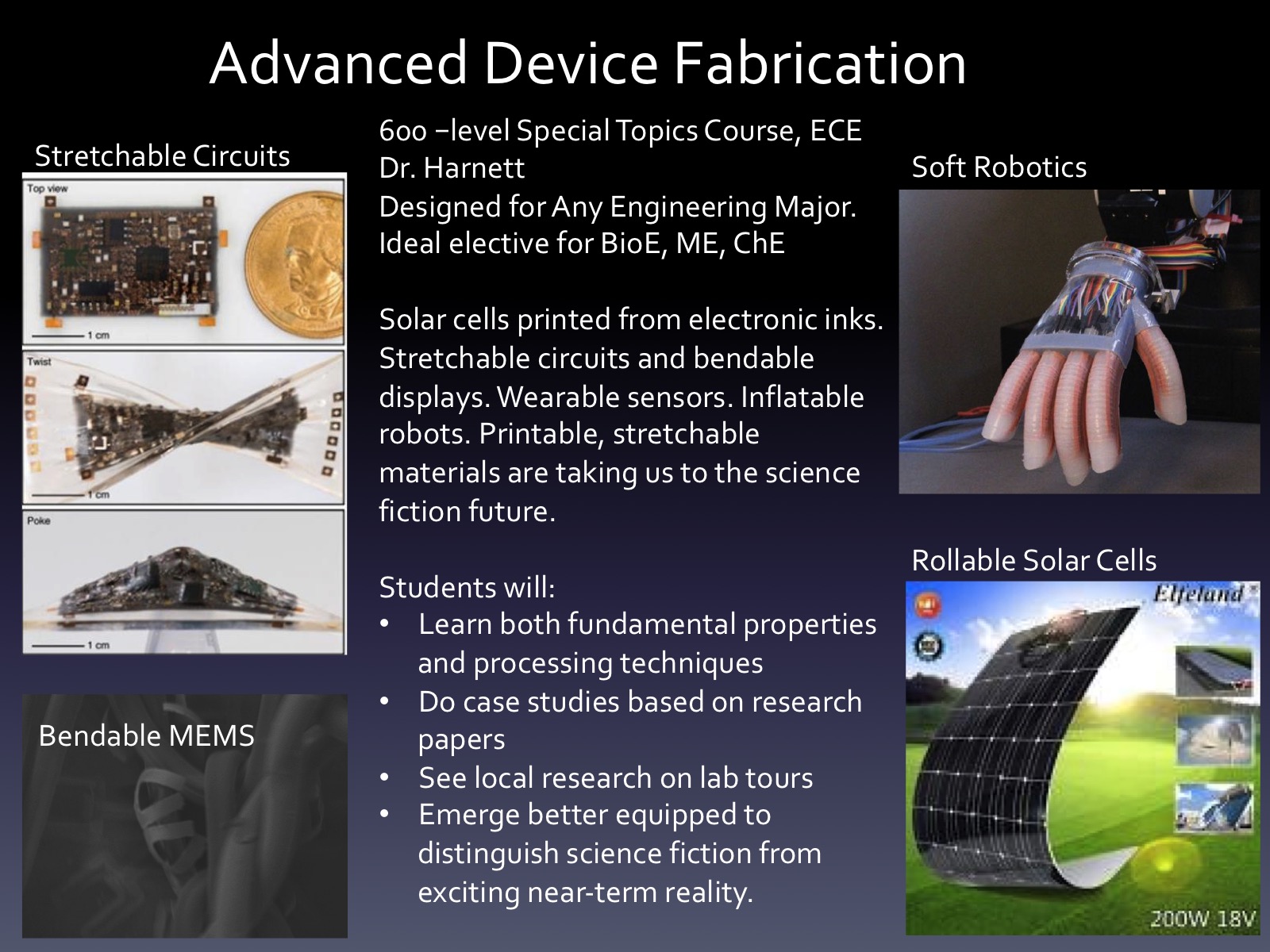

600-level research-based ECE course for all engineering majors.

3 credits.

What’s covered? More details here

Regularly Offered Courses in Electrical and Computer Engineering

ECE 412-Intro to Embedded Systems This course has students programming microcontrollers in C and assembly language. 412 is cross listed with CSE and is usually taught by me in the spring and fall, and Dr. Adrian Lauf (CSE) in the summer.

ECE 473-Intro to Electromagnetic Fields and Waves

ECE 322-Intro to ECE Computing Tools

ECE 100-Freshman Enrichment Experience

Learn to solder in the “Gadget Lab” sections of ECE100. Look inside consumer electronics, learn fundamentals of circuit construction and soldering, build and take home completed projects you select from a growing “menu” that includes: Solar Robot, Muscle Wire Actuator, Firefly LED Circuit, Electroluminescent Lamp, Solar Battery Charger, and Optical Theremin. Gadget Lab students recently built the Freeduino, a clone of the popular Arduino board.

ECE 569-Intermediate Electromagnetic Fields and Waves

GES 101-Introduction to Engineering (ECE Module)

Previous Independent Undergraduate and Masters Projects

Below are some recent semester-long student research projects. Research Experience for Undergraduate project topics are defined ahead of time, with some room for the student to customize to their research interests. Other project ideas are developed by the student in consultation with Dr. Harnett, and may be carried out for course credit (ECE 690/697, MS/M.Eng Paper Option). You’ll gather material for a conference presentation or publication and gain research experience in a new area. Students are routinely co-authors with our lab and sometimes co-inventors on patent applications. Want to discuss and find out more about whether this fits into your plan? Fill out the interest form on the “Join the Lab” page. And please try to plan ahead! Although deadlines are looser than registration for your other classes, there are only so many desks in the lab.

Previous Student Project: Optical Materials for Soft Robotic Sensors

These students developed some 3D printable soft optical components and a testing station for measuring optical properties of clear silicones under compression. Goal: a tactile sensor for soft robots. They are co-authors on conference presentations and research papers.

Previous Student Project: Force-Amplified Soft Magnetic Actuators

This student did electromagnetic simulations, tested the force output of soft magnetic linear actuators made by our wire layout systems, compared the two, and was first author on the resulting research paper.

Previous REU Project: MEMS Fiber Grippers

These students attached MEMS micro grippers to fiber arrays for mesh-suspended sensors. Applications are in wearables, air handling systems, tissue engineering, and soft electronics. This project is most active during summers and has led to a patent application and publication with student co-authors and more work in preparation.

Previous REU Project: Wireless Turbidity Sensor

This student learned to solder electronic circuits, then built and calibrated miniature turbidity (water cloudiness) sensor boards for our wireless environmental sensor project. The student also built a waterproof wiring system for the project, and by the end of the summer, drew up and assembled new circuit boards for power management. Results led to a conference presentation:

Previous Student Project: Carbon Nanotube Analysis

This student performed TEM (transmission electron microscopy) analysis of nanomaterials she deposited by high-temperature and plasma chemical vapor deposition within microreactors. The student presented results at a conference .

Previous Student Project: Induced-Charge Electroosmosis Devices

This student built and performed experiments with a microfabricated electrokinetic fluid mixer. Results from this work led to a publication .

High School Research Experience-Microfluidic Droplet Generator

A local high school student contacted our lab to work on a research project for their school science fair. During twice weekly visits, the student successfully built microfluidic droplet generators, tested them in our video microscopy system, designed new chips based on these early results, and helped develop a new fluid port system that we continue to use in this ongoing research area. Our technique is documented online at Chips and Tips.

Outreach and Online Education

Lab students and course students are encouraged to participate in outreach activities. Students are also asked to create online instructional content where appropriate, especially if they have developed a new process. The rapid feedback in an active online forum can be very helpful in learning how to accurately describe a research technique.

Engineering Day at the Louisville Science Center

“The Ohms Have It” In this interactive exhibit, visitors from ages 6 and up dismantled small electronics like cell phones. Samples from the University of Louisville Belknap Cleanroom showed fabrication steps of electronic components beginning from a silicon wafer. Student projects from the Gadget Lab course demonstrated some creative possibilities with only a handful of electronic components.

Chips and Tips: Integrated reservoirs for PDMS microfluidic chips

This online forum offers useful microfluidic fabrication techniques for a specialized audience. Here we entered our method to create inexpensive reservoirs in elastomer microfluidic chips using nylon tubes.

Instructables: How to make Flexible Printed Circuits

Instructables are great for sharing research and fabrication techniques. The simpler, cheaper and more accessible, the better (your ion etching recipes won’t find a large audience here, though someone will probably appreciate them) This is one from our lab.

Ponoko: Carbon Construction Kit

With more specialized processes that are available at outside companies, such as laser cutting, fabrication tips can sometimes be stored alongside the design file at the manufacturer’s site. Ponoko is especially good for sharing your designs.