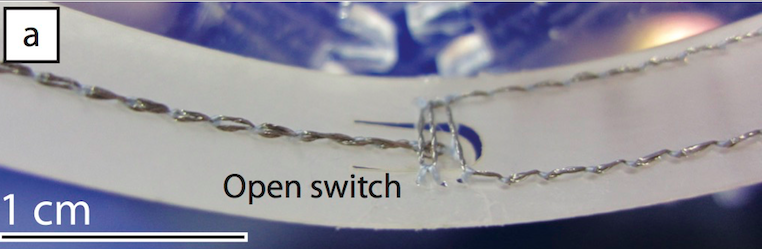

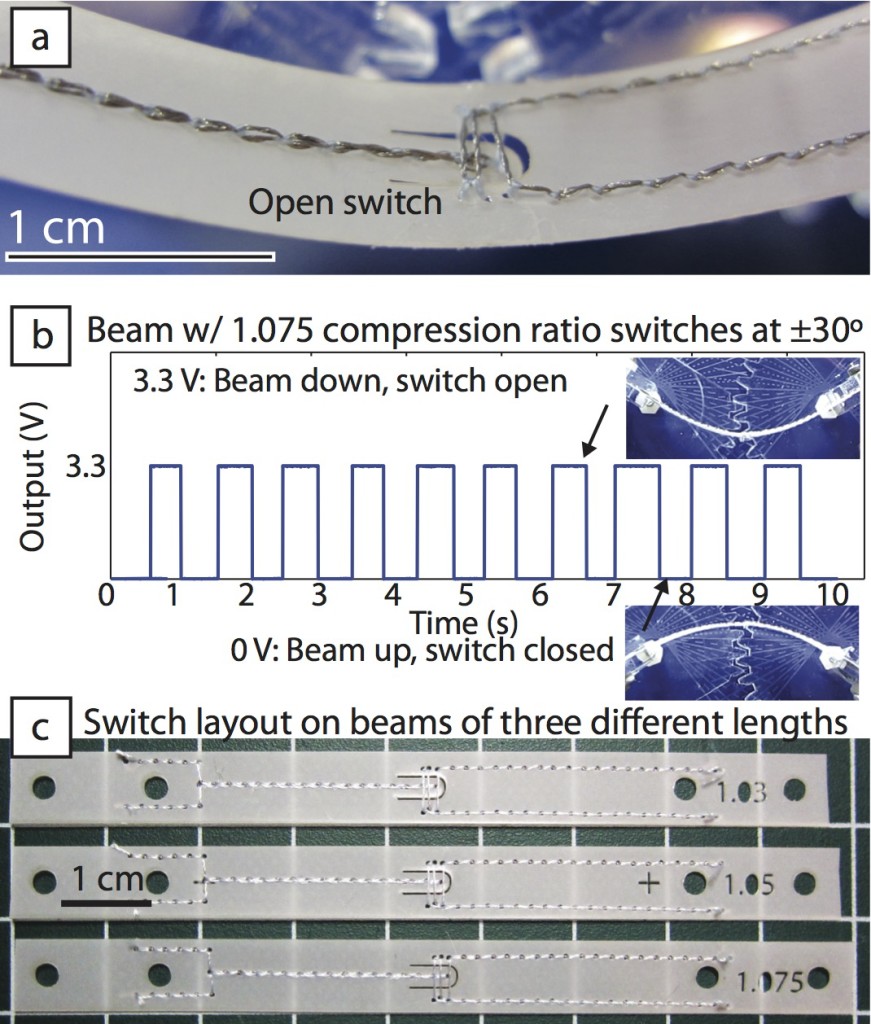

We have been dealing with bistable structures across different size scales. A common question is, how can we detect their state electronically. This project uses machine-sewable conductive thread to add an electronic switch to bendable compliant beams in a cm-scale structure. The beam material is 0.125 mm thick plastic film: thick enough to have some “snap” (video here) yet thin enough that a sewing needle easily punches through. In figure (a), silver-plated nylon conductive thread is suspended across a U-shaped cutout that has already had a conductive thread sewn down the middle. When the beam is down, the cutout moves away from the suspended threads, opening the circuit, and when it’s up, the threads are in contact. We can detect the beam position by connecting the switch to a digital input as shown in figure (b), it’s very crisp. In figure (c), there are a few different length beams that snap at different angles (paper here). The embroidered pattern needed to be aligned to these laser-cut beams, and to do that a pair of “+” shaped alignment marks helped line up the needle. Those marks can be seen on the middle beam, except the left one is stitched over so it’s hidden. This flexible design is a big improvement over a previous iteration (video here) where we had soldered on switches that kept flying off.